Introduction to Compressor Used in CNG Vehicle Gas Station

The compressor used in CNG vehicle gas station is designed and developed to adapt to the CNG vehicle gas station away the pipe network gas stations and processing high and low variable conditions. which conforms to the gas characteristics, avoids the high failure rate, large noise high energy consumption and other faults existing in positive displacement compressor of current CNG vehicle gas station, highly improves the energy consumption rate and operation rate free of troubles. Comparing with common compressor, this compressor reduces the energy consumption by 50-60%, which is good at environmental protection, saving energy and high efficient and a specialized compressor for CNG vehicle gas station.

Ⅰ.

Saving energy

The ABB explosion-proof motor is adopted in this system as its power source and the hydraulic system is used to drive the piston of gas cylinder for the purpose of compressing the gas in cylinder to realize the compression and pressurization of natural gas. The operation in different work conditions is used in design, namely the single-set running (the power of the running motor is 37KW) and double-set running (power of the running motor is 74KW) can be selected according to the difference of gas supply and usage. It reduces the energy consumption and improves the efficiency. If the pressure between entering air and discharged air is extremely large (≥10Mpa),the hydraulic variable pump can be used to ensure the safety of the motor and the smooth of gas supply in different work conditions. The fluid drive used can decrease the noise effectively, and meanwhile the driving element is operating in hydraulic poise so that it decreases the abrasion and increases its service life. The amount of gas input and discharged by the modern 37KW single-set running compressor is equivalent to that of the former 90KW compressor.

Ⅱ. Environmental protection

The symmetric balanced design is applied to this machine, and the lubrication without oil, wind and water mixing cooling and two-stage segregating filtration make the gas much clearer. Heat balance calculation is done in the design and the totally closed recycling cooling system is adopted. There will not be the problem of discharging exhaust gas and waste water during the operation because the equipment has no residual gas when it stops. Having no pollution to the environment, Truly realized energy (gas consumption、water consumption、fuel consumption),emission reduction and environmental protection.

Ⅲ. Reliability of equipment operation

The motor, electric appliance, control system, hydraulic pump, valve, pipeline and connections are all produced by international famous company, which are high in quality and good in performance. The optimum design of man-machine engineering makes equipment easy to operate, good in maintainability and low in maintenance cost.

Ⅳ. Automation of the equipment operation

The automation degree of the equipment operation is high, as the equipment is installed with temperature control device, pressure testing control device, automatic turning control device and automatic protecting device for hydraulic pump. The operation of the equipment is controlled automatically, being safe and reliable.

Ⅴ. Replacement of spare parts

70% of spare parts installed on this equipment are produced by international famous enterprises and the left are fabricated by this company. The complete machine has few wearing parts and short maintenance time, and the wearing parts have long service life; the model of spare parts are quite common, widely applied in the market and easy of purchase.

The main technical parameter of product

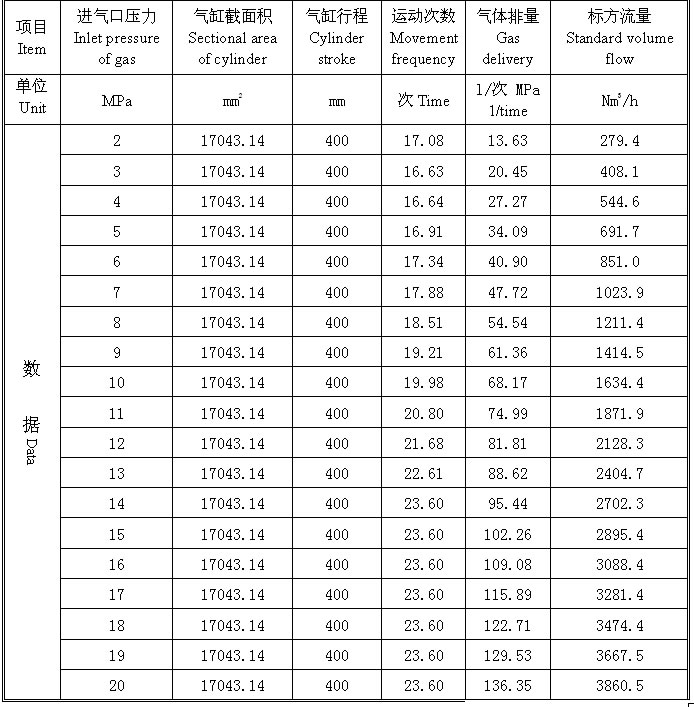

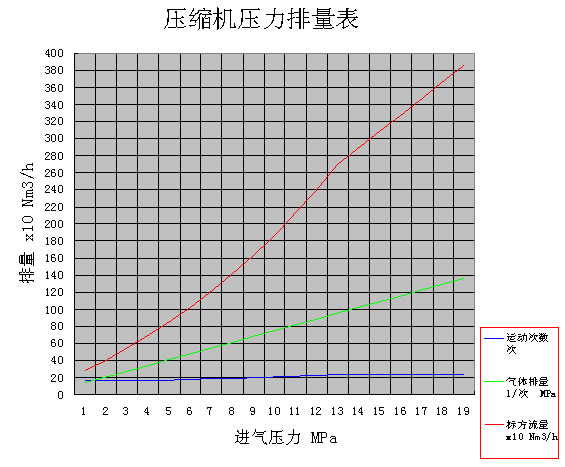

Appendix 1 parameter table of deliver

Movement frequency

Time

Gas delivery

1/Time MPa

Standard Volume flow

х10 Nm3/h

Hydraulic pressure parts

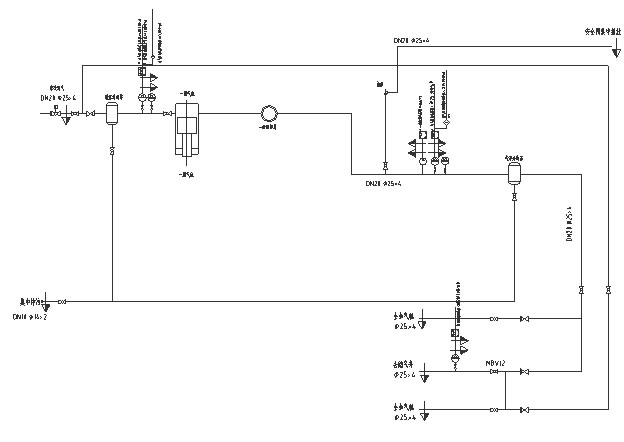

Flow process diagram of compressor gas path

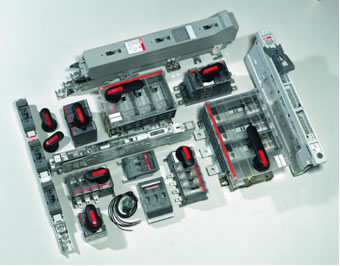

Electrical control part

ABB Softstarter ABB switching fuse protector bank

ABB circuit breaker Control cabinet

?? All of adopted equipment motors and electrical components are from ABB company; mainframe is driven by ABB soft starter, which is reliable and superior, and is matched with Siemens PLC to realize the full automation control operation of the equipment.

|